Technology

Bursting Test of Fabric: Methods, Importance, and Applications

Published

6 months agoon

By

Admin

Introduction

The bursting test of fabric is a crucial procedure in the textile and fabric manufacturing industry. It evaluates a fabric’s resistance to multidirectional stress or pressure. Unlike tensile tests that measure resistance to pulling in a straight line, bursting tests simulate real-world forces where pressure may act in multiple directions—such as when a fabric is stretched over a curved surface or inflated from within. This makes the bursting test especially important for knitted, nonwoven, and technical textiles.

This article explores what the bursting test of fabric entails, why it’s important, how it’s performed, and where it’s commonly applied.

What Is the Bursting Test of Fabric?

The bursting test determines the bursting strength of a fabric, defined as the pressure required to rupture the fabric when it is subjected to force applied perpendicularly to its surface. This is particularly relevant for materials that undergo pressure in all directions rather than just linear tension.

Bursting strength is generally expressed in units such as kilopascals (kPa), pounds per square inch (psi), or Newtons (N), depending on the testing method and standard used.

Why Is the Bursting Test Important?

The bursting test provides valuable information about the durability, safety, and performance of fabrics in everyday and industrial applications. Its importance includes:

- Performance assurance: Ensures fabric can withstand real-world multidirectional pressure.

- Product safety: Prevents failure in high-pressure or critical applications like airbags or medical textiles.

- Quality control: Verifies that fabric batches meet industry or client specifications.

- Material selection: Assists designers in choosing fabrics suitable for specific environments or stress conditions.

- Standard compliance: Many industries require bursting strength data for product certification.

Fabrics Commonly Tested for Bursting Strength

While any fabric may undergo bursting tests, it is especially critical for:

- Knitted fabrics: Due to their looped structure, knits are more prone to stretch and burst than wovens.

- Nonwoven fabrics: Often used in filtration, medical textiles, and disposable products.

- Composite or coated fabrics: Used in upholstery, industrial gear, and packaging.

- Technical textiles: Fabrics used in airbags, safety equipment, or geotextiles.

Methods for Bursting Test of Fabric

Two main methods are commonly used to perform the bursting test of fabric:

1. Hydraulic (Diaphragm) Bursting Test

Standards: ASTM D3786, ISO 13938-1

How It Works:

- The fabric is clamped securely over a rubber diaphragm.

- Hydraulic fluid is pumped under the diaphragm.

- As the pressure builds, the diaphragm bulges and exerts force on the fabric.

- The pressure continues to rise until the fabric bursts.

- The peak pressure at which rupture occurs is recorded as the bursting strength.

Advantages:

- Ideal for stretchable and flexible fabrics.

- Simulates uniform, multidirectional pressure.

2. Ball Burst Test

Standard: ASTM D3787

How It Works:

- A steel ball is pushed mechanically through the center of a clamped fabric sample.

- The force required to push the ball until the fabric breaks is measured.

- More suitable for rigid or less stretchable fabrics.

Advantages:

- Simple setup.

- Useful for thick, multi-layered, or coated textiles.

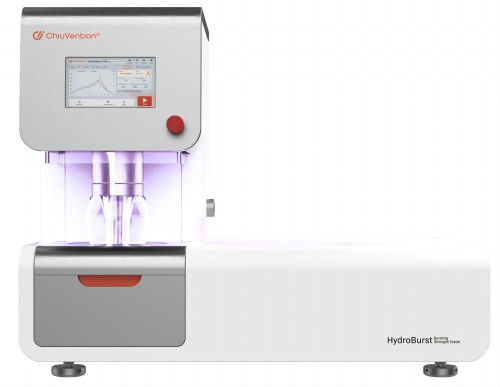

Equipment Used in Bursting Tests

Key equipment includes:

- Bursting Strength Tester: A hydraulic or mechanical machine designed for fabric testing.

- Clamping Device: Holds the fabric tightly in place.

- Pressure Gauge or Load Cell: Measures the force or pressure applied.

- Digital Interface: Records test results and generates stress-strain curves or pressure data.

Advanced machines allow programmable settings for test speed, pressure build-up, and result reporting.

Factors Affecting Bursting Strength

Several factors influence how a fabric performs in a bursting test:

- Fiber type: Strong synthetic fibers like polyester or nylon offer better resistance than natural fibers like cotton or wool.

- Fabric construction: Knitted fabrics generally have lower bursting strength than woven fabrics due to their stretchability.

- Yarn twist and density: Higher twist and tighter weave or knit improve bursting resistance.

- Finishes and coatings: Laminated or resin-finished fabrics often show increased bursting strength.

- Environmental conditions: Humidity, temperature, and fabric moisture content can affect test outcomes.

Applications of Bursting Test Results

Bursting test data is vital in many industries:

- Apparel: Sportswear, underwear, and activewear require high stretch resistance.

- Medical textiles: Surgical gowns, wound dressings, and disposable medical fabrics.

- Home furnishings: Upholstery, cushions, and mattresses must endure regular pressure.

- Industrial applications: Sacks, tarpaulins, filters, and geotextiles.

- Safety and protective gear: Airbags, gloves, and military textiles.

In all these applications, the fabric’s ability to resist bursting is directly linked to product durability and user safety.

Bursting Test vs. Tensile Test

| Feature | Bursting Test | Tensile Test |

| Force Direction | Multidirectional (all directions) | Unidirectional (linear) |

| Suitable For | Knits, nonwovens, soft fabrics | Wovens, yarns, composites |

| Use Case | Pressure resistance | Pull resistance |

| Common Standards | ASTM D3786, ISO 13938-1 | ASTM D5035, ISO 13934-1 |

Conclusion

The bursting test of fabric is a vital mechanical assessment that reveals how well a fabric can endure multidirectional pressure before failure. It’s especially relevant for flexible or stretchable materials like knits and nonwovens, and its results are crucial for ensuring fabric performance, safety, and durability in real-world applications. By using standard methods such as ASTM D3786 or ISO 13938-1, manufacturers can ensure consistent quality and reliability in their textile products.

As fabric innovation continues—especially in smart textiles, medical fabrics, and technical textiles—bursting strength testing will remain a foundational part of fabric evaluation and certification.

For more information on textile testing methods/standards

or textile testing machines, contact us:

What’s App: +86 180 2511 4082

Tel: +86 769 2329 4842

Fax: +86 769 2329 4860

Email: sales@tes.hk

Graduations, Pouch Pizza, Purchase Games, and ZipperGitsFh: A Modern Digital Culture Story

Unlock the Thrill: Why Independent Casinos Sites Are Better

The End of Forms: Why No-Registration Casinos Are Taking Over

The Best Online Casinos: Why Experience Matters More Than Luck

Understanding “inurl:home.htm intitle:1766” and Why People Search It

Home Gym Meteorology Shop: Evaluating Fitnara for Smart Fitness Choices

The Future of Gaming is in Your Hands: Why PayByMobile Casinos Change Everything

Discover the Elite: Why the Top 50 Online Casinos UK Set the Standard

Unleash the Thrill: Discover the Ultimate Experience at Basswin Casino

The Gold Standard: Defining the Best Online Casinos in the UK

The Gold Standard: Defining the Best Online Casinos in the UK

Discover the Elite: Why the Top 50 Online Casinos UK Set the Standard

Unleash the Thrill: Discover the Ultimate Experience at Basswin Casino

Fresh Spins & Big Wins: Unlocking the Best New Casino Bonuses in the UK

Home Gym Meteorology Shop: Evaluating Fitnara for Smart Fitness Choices

The Future of Gaming is in Your Hands: Why PayByMobile Casinos Change Everything

The Best Online Casinos: Why Experience Matters More Than Luck

Understanding “inurl:home.htm intitle:1766” and Why People Search It

The End of Forms: Why No-Registration Casinos Are Taking Over

Unlock the Thrill: Why Independent Casinos Sites Are Better

Graduations, Pouch Pizza, Purchase Games, and ZipperGitsFh: A Modern Digital Culture Story

Unlock the Thrill: Why Independent Casinos Sites Are Better

The End of Forms: Why No-Registration Casinos Are Taking Over

The Best Online Casinos: Why Experience Matters More Than Luck

Understanding “inurl:home.htm intitle:1766” and Why People Search It

Home Gym Meteorology Shop: Evaluating Fitnara for Smart Fitness Choices

The Future of Gaming is in Your Hands: Why PayByMobile Casinos Change Everything

Discover the Elite: Why the Top 50 Online Casinos UK Set the Standard

Unleash the Thrill: Discover the Ultimate Experience at Basswin Casino